Varied and complex, inter-dependent competencies are required for a metal component to be designed-engineered, manufactured, proven out and produced in volume using 3D printing. Advanced know-how of Additive Design & Engineering principles, a well-synchronized pre-build, in-build and post-build strategy, experience in process control, characterization capabilities and strong post-processing execution, govern successful usage of metal AM in mainstream business operations.

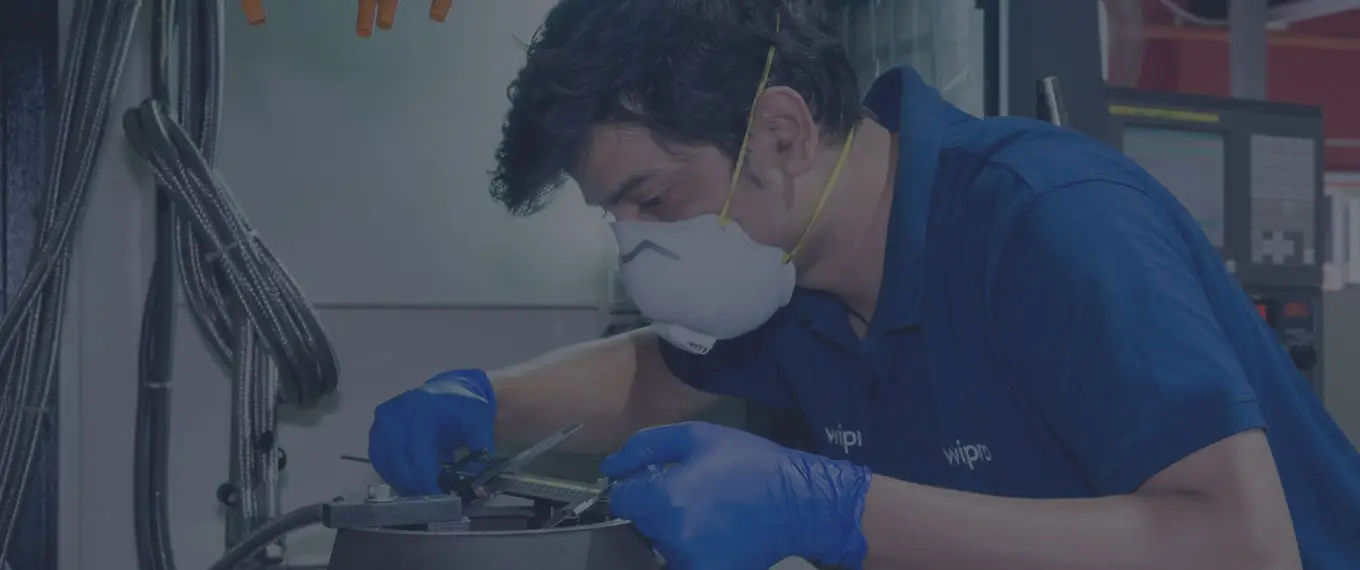

Wipro 3D’s operates a leading edge metal 3D printing centre that is a comprehensive, multi-purpose metal Additive Manufacturing facility, offering Additive Consulting, Additive Design & Engineering Solutions, Contract Manufacturing Services as well as Research & Development services, customized to meet the business imperatives of our customers.

Wipro 3D has offered direct metal 3D printing solutions for all the industry sector – Aerospace, Automotive, Space, Healthcare , Nuclear and etc.,Wipro 3D has designed its leading edge metal 3D printing centre, to serve as a hands-on workshop site, an experience center as well as a 3D printing Center of Excellence that enterprises and decision makers, to be able to define their metal AM journey, estimate the effort, skill ramp up, investments, and finally business case, need to explore the entire realization lifecycle of a metal AM component. Variety of direct metal 3D printing solutions are available in metal 3D printing processes. Our 3D Printing center of excellence serves as the direct metal 3D printing solutions providing center for all business cases ensuring successful outcome. Wipro 3D offers the best 3D printing solutions by powering your business with digital manufacturing process.

The Metal AM facility offers just that; a hands-on experience to work with the technology and understand what it takes to work with Metal AM. Additionally, we work with customers to define their AM roadmap right from identifying the right use cases, through to component optimization and realization, through workshops and pilot arrangement. Our direct metal 3D printing solution center is designed keeping this customer need in mind, apart from its core purpose of providing services.

The center will also house Wipro 3D’s ecosystem partners. A critical part of Wipro 3D’s strategic blueprint is to create a robust ecosystem of aligned partners. The Wipro3D Metal AM centre will act also a 3D printing center of excellence for Additive Manufacturing solution providers, such Metal AM printer Manufacturers, Post Processing Solution Providers, Research and Development Partners, to participate in the Wipro Additive Manufacturing ecosystem

In the emergence of 3D printing technology, Wipro 3D serves as the leading 3D printing center of excellence for enterprises which transforms the production industry in this digital manufacturing era. The facility also serves as an 3D printing COE Center- of- Excellence Template, for organizations who are considering using Wipro 3D’s Turnkey solutions to set up their own captive metal 3D printing Center.

All infrastructure in our AM facility is oriented and goaled on research and development, improvement in practices and methodologies. We offer dedicated solutions for Research and Development needs of our customers using our own in-house equipment that contains best in class characterization equipment, build monitoring and simulation methods, as well as customize process parameters.

Using best-in-class metal AM printers, post processing and characterization equipment, we offer Contract Additive Manufacturing Services that serve production and aftermarket needs of our customers across Industry Verticals. Process Packages created by the Design and Engineering team are realized with high fidelity using W3D Manufacturing Standards, that dovetail with Quality Standard requirements for certifications such such as AS9100 Rev D, NADCAP, Llyods Register.Wipro3D’s complete suite of capabilities that including Additive Consulting, Additive Engineering, Quality and Manufacturing systems allow us to offer world class Contract Additive Manufacturing services to clients globally

The facility houses a Additive Design and Engineering Studio comprising of Application Experts, Metallurgists, Post Processing Experts and Turnkey Project Managers. We use best-in-class Simulation, Additive Design, Topology Optimization software added to our cross functional expertise, to create customized process packages specific to our customer’s applications.

Wipro 3D plans to be a cross platform solution provider with solutions based on Selective Laser Melting or Powder Bed fusion, Electron Beam Melting, Binder Jetting as well as Direct Energy Deposition processes.

The current machine capability includes M400, M290 and an M280. Best practices in powder characterization, conditioning, handling storage and tracking are followed on the shop floor including best in class safety and environment monitoring. Infrastructure includes remote (including visual) monitoring of builds.

Know MoreThe main engine of our R&D activities for process and parameter development, the lab consists of best-in-class equipment including Optical Microscope, Scanner, CMM, and a range equipment including an ONH Analyzer.

For additional analysis, we have use the capabilities of an additional in-house lab as well as strategic relationships with various OEMs and research institutions.

Know MoreWe use a range of design tools for modelling, topology optimization, simulation, build preparation, as well as build management software. We leverage Wipro’s in-house product engineering expertise for specific customer requirements.

Plan vs Actual results are an integral part of the manufacturing culture that constantly feed into our design and engineering capabilities.

Know MoreAll machines and processes required right from the build release and post build heat treatment, net shaping to surface are put under one roof for a productive and smooth workflow, enabled by custom designed material handling capabilities.

Wipro 3D designs some of its key machines in post processing to be able to customize parameters for achieving required results.

Know MoreThe Wipro 3D team has deep multi-discipline understanding of functional applications and the metallurgical challenges of AM. Our team includes materials sciences specialists and AM advisors, tech experts who understand different types of metals and their attributes; and highly experienced specialists in the area of sintering, fusion and adhesive binding.