Why Metal Additive

Manufacturing?

Services

Wipro 3D Capabilities

Wipro 3D provides end-to-end additive manufacturing solutions, including metal 3D printing, backed by a metallurgical lab and quality systems, along with specialized post-processing and cutting-edge software tools, with proven expertise across diverse metal materials.

Diverse Metal Materials

Wipro 3D supports a wide range of industrial-grade alloys for additive builds:

Ti

TitaniumTitanium Alloys

Strong, lightweight, and corrosion-resistant for aerospace and medical applications

Al

AluminumAluminum Alloys

Functional prototypes and series-production parts

Ni

NickelNickel Alloy

Excellent mechanical strength and resistance under stress

Co

CobaltCobalt-Chrome Alloys

Wear-resistant and biocompatible; used in dental and aerospace applications

Custom Alloys

AM parameters crafted to meet specific customer requirements

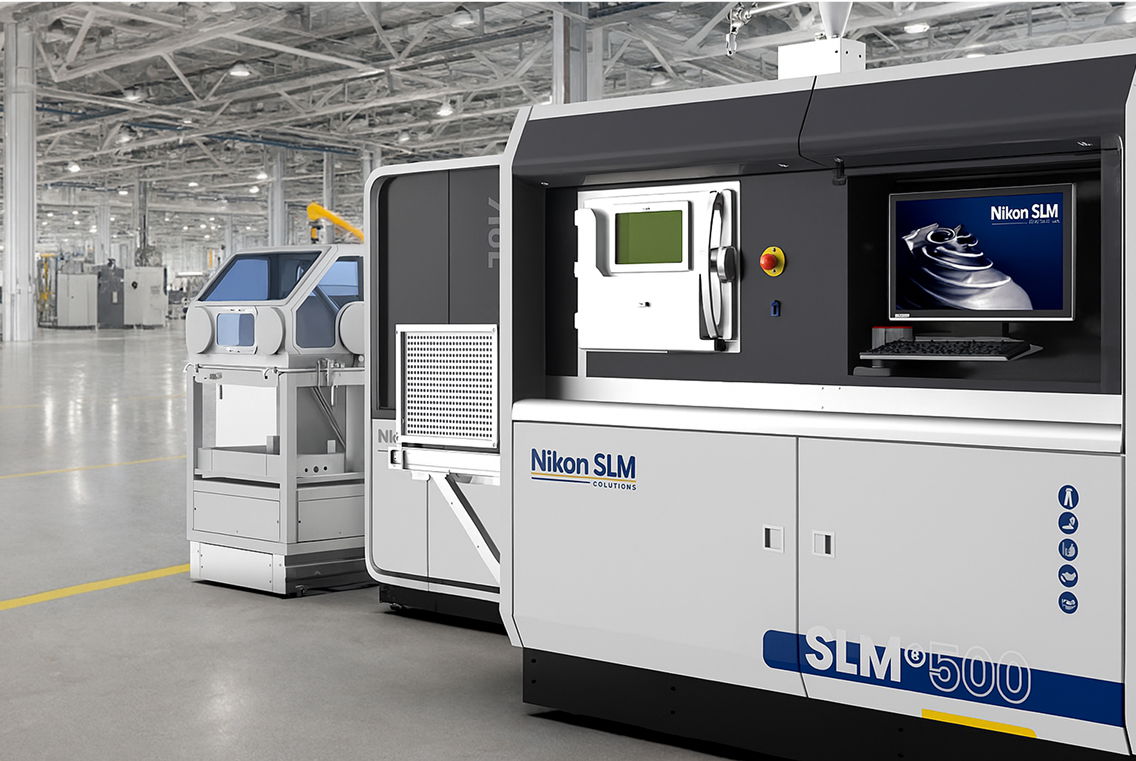

Metal Printing Capabilities

Laser Powder Bed Fusion (LPBF), also known as selective laser melting (SLM) or direct metal laser sintering (DMLS), is a laser-based process that selectively melts metal powder to create specific parts or components.

| SLM Machines | Build Envelope (mm3) |

| SLM®500 Quad Laser | 500 X 280 X 365* |

| EOS M400 | 400 X 400 X 400* |

| EOS M290 | 250 X 250 X 325* |

| EOS M280 | 250 X 250 X 325* |

* Build Envelope is inclusive of build plate thickness.

From Concept to Production

Consultation & Feasibility Review

Based on customer requirement, Wipro 3D will recommend the right AM technology and substitute material if required along with AM value addition to improve the functionality and cost reduction.

DfAM & Simulation-Driven Optimization

Provide enormous freedom to the designers by giving solutions such as part consolidation, topology optimization, light weighting and complex geometry realization through process simulation.

Build Setup & Controlled Printing

Choose the best orientation, support strategy and laser parameter to get the best part quality output and control these through a robust process plan.

Post-Processing & Validation

Post-processing the part to ensure the final part meets all drawing requirements. Validate that the part is defect-free through various NDT techniques.

Certification & Inventory Digitization

Enable quality management systems and ensure compliance with international and industrial standards. Additionally, promotes optimize the physical inventory through digitization of the relevant spare parts and manufacturing them on demand.

Case Studies in Metal 3D Printing

Industry Applications

Wipro 3D’s metal print services are engineered to meet the critical demands of diverse industry sectors, delivering complex geometries with consistent quality, mechanical integrity and compliance with industry standards.

Aviation, Space & Defence

Explore More

Oil, Gas & Energy

Explore More

Automotive & Industrial

Explore MoreWhy Wipro 3D?

Additive Expertise

Proven leadership in metal AM engineering & consulting

Wipro's Scale

Trusted by defence, aerospace, automotive and oil & gas leaders.

Global Footprint

Manufacturing excellence across world-class facilities

Industrial Intelligence

Engineering-led AM solutions tailored to your use case

Quality Certifications

Quality Certifications

- End-to-end support for product qualification, including in-house testing.

- Nadcap & API 20S: Standards for quality, reliability and precision.

- ISO 9001, ISO 27001, and EN/AS9100 compliance across industries.

- Secure handling of proprietary data with secure digital workflows.

- Traceable production logs for regulatory and engineering confidence.

NADCAP Accredited

ISO 9001 : 2015

EN 9100: 2018

API 20S Compliance

ISO 27001

Ready to Integrate Metal AM Into Your Production Workflow?

Wipro 3D offers end-to-end metal additive manufacturing solutions, encompassing design, process validation, production, and post-processing.

- Design & application engineering

- Digital workflows & data management

- Machine setup & optimization

- Post-processing & quality control