Why Polymer Additive Manufacturing?

Services

Wipro3D Capabilities

Wipro 3D offers end-to-end polymer additive manufacturing solutions with advanced 3D printing, quality systems, and post-processing. With expertise in a wide range of polymer materials, we ensure reliable and high-performance results tailored to diverse industry needs.

Diverse Polymer Materials

Choose from a broad library of high-performance polymers and engineering-grade materials:

PLA / ABS / PET-G / HIPS

General-purpose, tough thermoplastics

TPU / TPE

Flexible materials for dynamic parts and wearables

Nylon & Nylon-CF

Strong, lightweight, with good chemical resistance

Polycarbonate (PC-FR)

Excellent dimensional stability and fine surface finish

Standard & Tough Resins

For high-detail prints with optional castability

Custom Blends

Tailored filament or resin for niche applications

Polymer Printing Capabilities

To meet both industrial and functional requirements, polymer additive manufacturing solutions support the full journey from prototype to production.

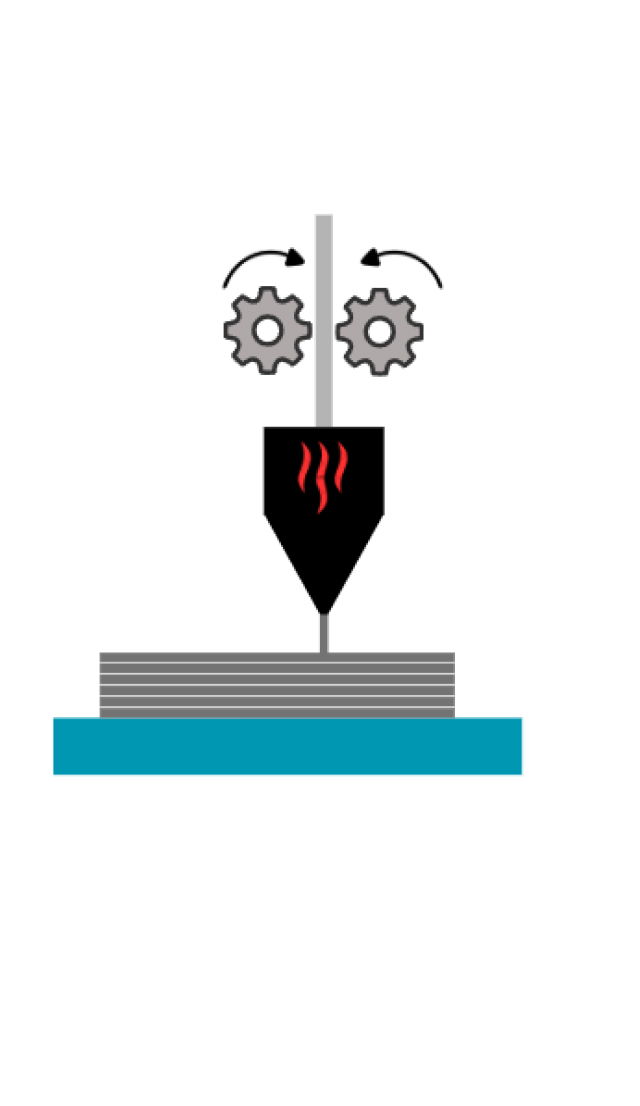

FFF - Fused Filament Fabrication

FFF involves depositing a thermoplastic material, layer by layer based on the sliced CAD file to produce a part.

Materials:

PLA, ABS, ASA, HIPS, PET-G, Nylon, Nylon-CF, TPU, TPE, PVA and many more available in multiple colors.

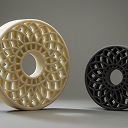

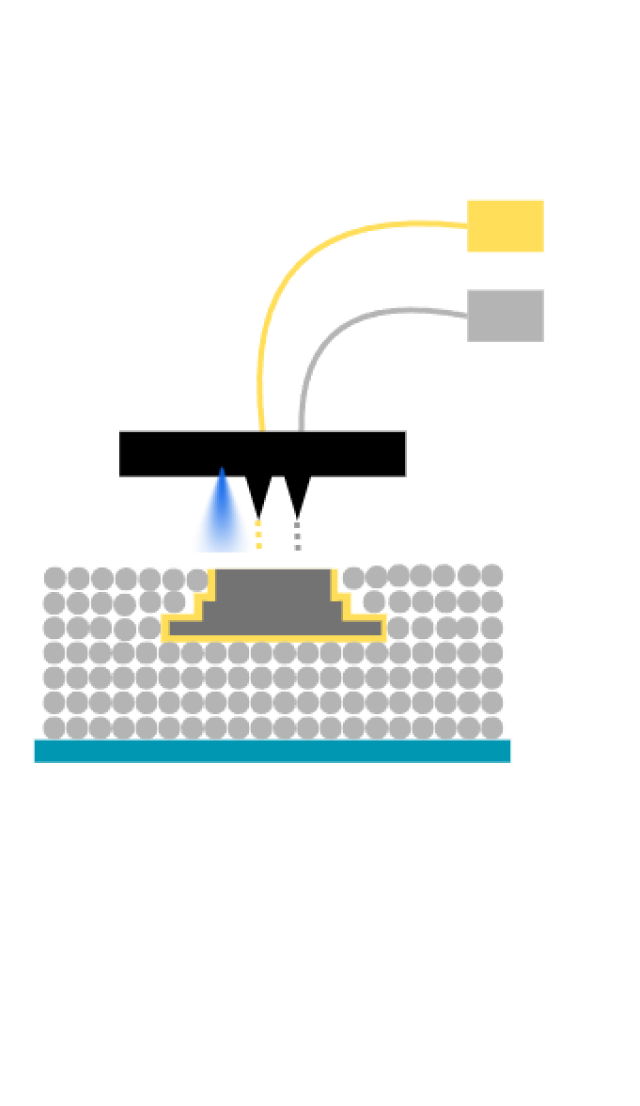

MJF – Multi Jet Fusion

MJF (Multi Jet Fusion) technology enables the production of versatile and complex geometries without the need for support structures, and it offers the option for multicolor output. The process uses an array of inkjet nozzles to selectively deposit binding and color agents onto the powder bed, layer by layer. These areas are then fused using a fusing lamp, corresponding precisely to the sliced geometry of the part.

Materials:

Nylon PA12

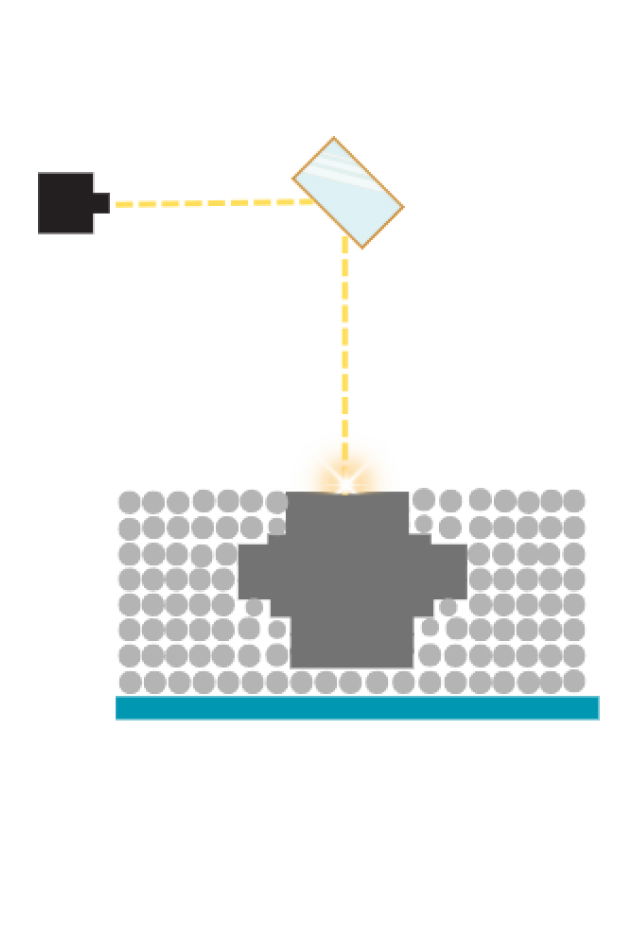

SLS - Selective Laser Sintering

Selective Laser Sintering (SLS) is a polymer powder bed fusion process in which a laser is used to selectively fuse powder layer by layer, producing detailed and support-free components. SLS is well-suited for both functional and prototype applications.

Materials:

Nylon, Nylon-CF, Nylon-GF, TPU and many more.

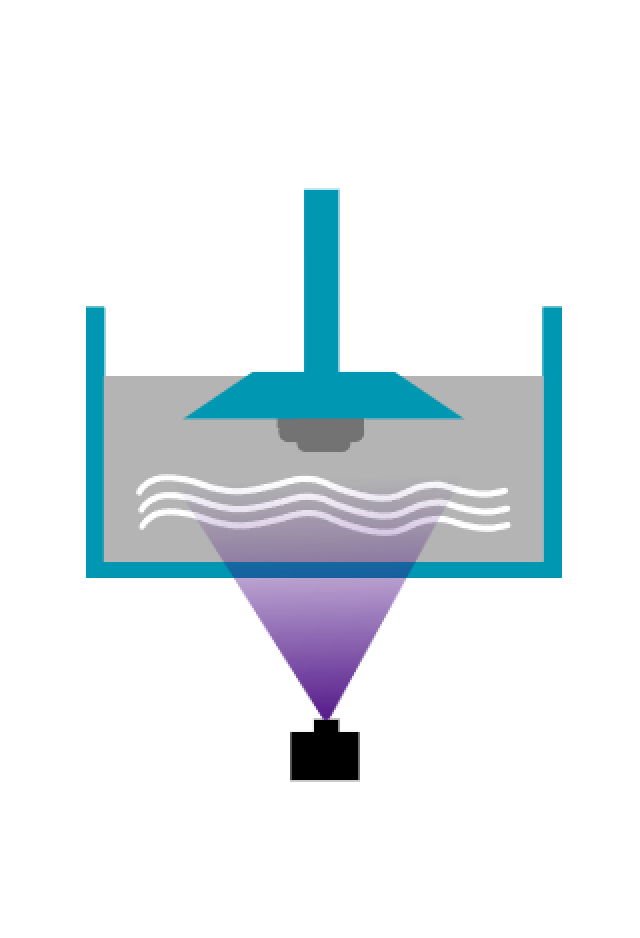

DLP - Digital Light Processing

DLP is a 3D printing technology that uses a light projector to selectively cure liquid resin, layer by layer. The projector displays the image of each layer onto the resin surface, which then solidifies upon exposure to specific wavelengths of light resulting in highly precise components.

Materials:

Resin

From Concept to Production

Consultation & Feasibility Review

Assess the project scope, suggest suitable print technologies, and leverage additive manufacturing to improve functionality and optimize costs.

Part Design & Material Recommendation

Enhance the design, select the right materials, and ensure a cost-efficient outcome.

Printing & Finishing

Print the part using the optimal orientation and packing factor, followed by necessary post-processing steps such as support removal, sandblasting, waxing, smoothing, and painting.

Testing & Validation

Conduct rigorous testing and inspection to ensure the part meets quality and performance standards, including dimensional accuracy and surface finish requirements.

Packaging & Delivery

Deliver the finished product with suitable packaging and logistics, along with necessary documentation.

Why Wipro 3D?

Polymer Expertise

Deep knowledge across FFF, MJF, SLS and DLP

Design & Engineering Support

From CAD to simulation

Production-Grade Capability

Industrial printers for fast turnaround

Custom Engagements

Tailored materials and pilot builds

Ready to Accelerate Product Development with Polymer AM?

Wipro 3D helps you build better, faster with high-performance polymer 3D printing.

- Application & material consulting

- Rapid part iteration & testing

- Batch production or pre-launch pilot runs