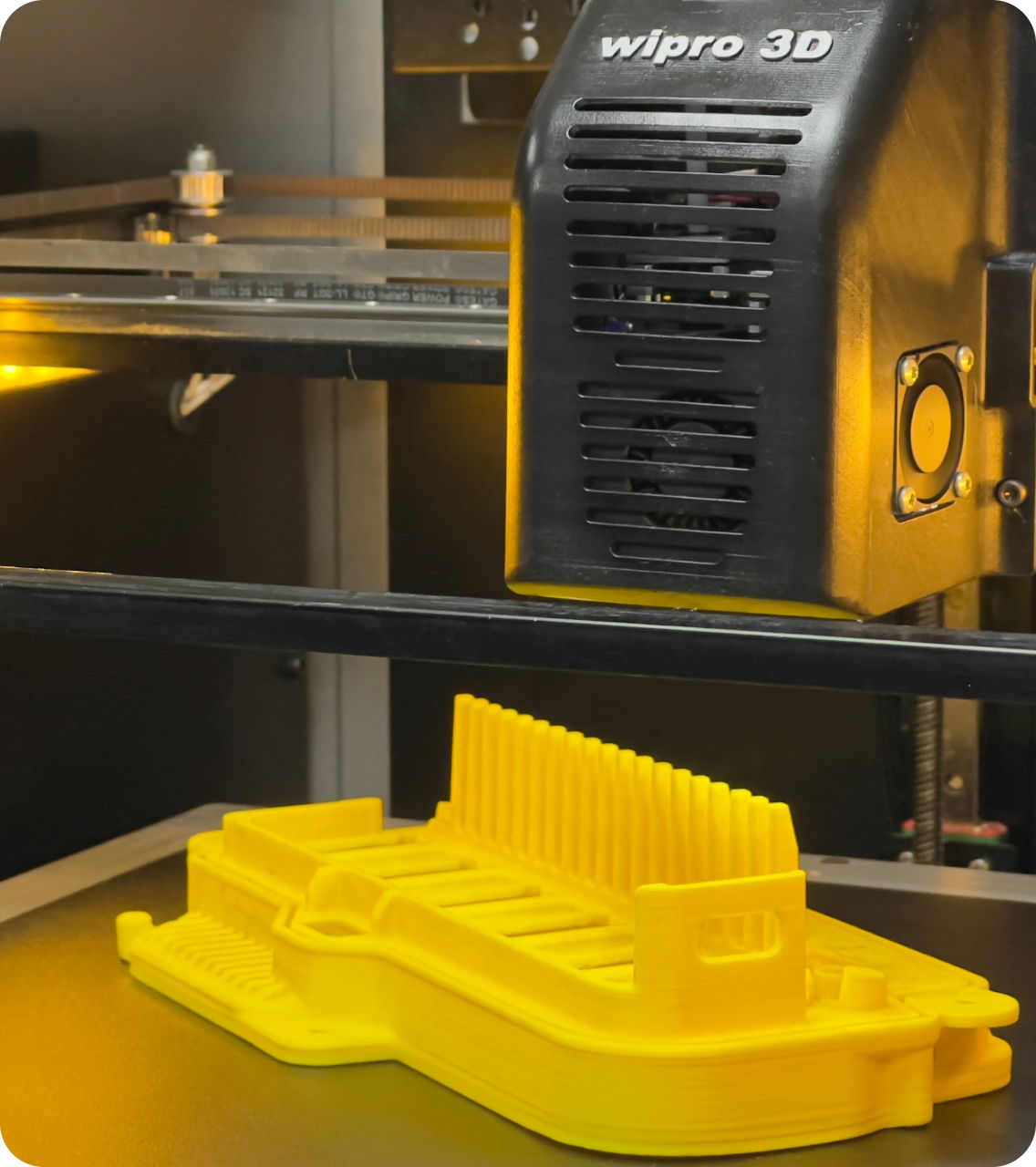

Wipro 3D F300 Series

Industrial 3D Printer

Meet the F300 – Wipro 3D’s next-gen FFF 3D printer, purpose-built for industrial-grade polymer printing. With configurable single/dual-nozzle system, temperature-monitored chamber and highly stable build plate, it delivers high-quality, repeatable parts across a wide range of functional applications.

Key Highlights

- Compatible with engineering-grade polymers

- Intelligent 3-Point Bed Leveling

- Smart Material Detection

- Print Size: 300 x 300 x 300 mm