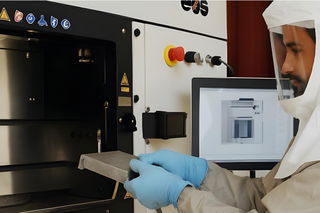

Manufacturing Facility

Design & Engineering Hub

Research and Development

Ready to See Wipro 3D Infrastructure in Action?

Connect with us to schedule a visit or explore how our facilities can accelerate your AM journey.

Wipro 3D’s Additive Manufacturing (AM) infrastructure is anchored in an advanced, scalable facility that supports seamless production integration and skill development. With cutting-edge machinery, we deliver high-quality components across industries such as Aerospace, Space, Oil & Gas, Defence, Automotive, and Energy. We operate as a premier 3D Printing Center of Excellence (CoE), driving the transformation of industries toward the digital manufacturing era.

Connect with us to schedule a visit or explore how our facilities can accelerate your AM journey.